Home > Solutions for Buildings > Cyclone 360

CYCLONE 360°

Advantages of Cyclone 360 ventilation for dairy farming

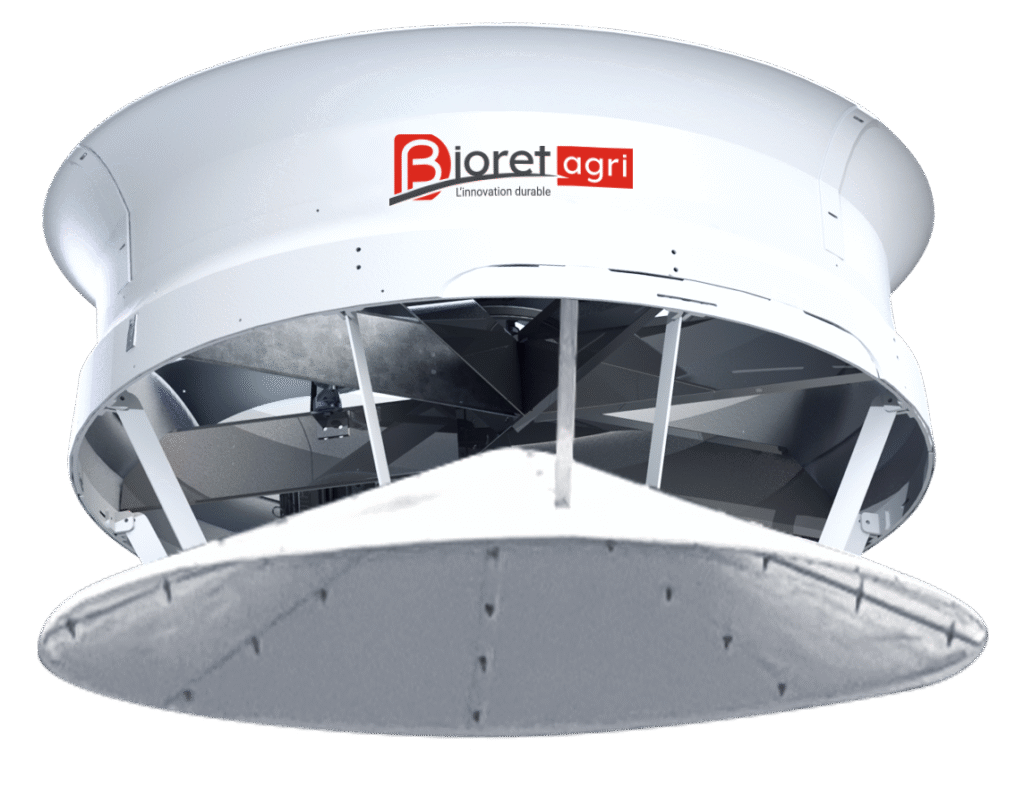

Cyclone 360: Consistent and effective ventilation

The Cyclone 360 distributes a constant and consistent airflow over 360 degrees, from ceiling to floor. It destratifies the air and eliminates hot or stagnant zones in the building. Thanks to an adjustable air speed of 0.5 to 2.5 m/s, it provides an immediate feeling of freshness on the backs of the cows, even during periods of intense heat.

This continuous air circulation reduces the perceived temperature and quickly dries the floors, thus limiting the risk of slips and foot pathologies.

Its low-consumption brushless motor technology ensures energy savings of up to 32% compared to a conventional fan, while guaranteeing quiet, smooth and durable operation. Designed with robust materials, the Cyclone 360 is perfectly resistant to the constraints of livestock farming and is a reliable investment to improve the comfort and performance of your herd.

Two sizes to fit all buildings

The Cyclone 360 is available in two sizes to meet height constraints and air volume requirements:

Cyclone 360 / 72″: diameter 2.12 m, airflow of 80,000 m³/h, range of 14 to 18 m, ideal for buildings with high ceilings.

Cyclone 360 / 52″: diameter 1.62 m, airflow of 40,500 m³/h, range of 8 to 12 m, designed for lower structures.

Whatever model you choose, you benefit from consistent and powerful ventilation. It effectively reduces heat stress and promotes the health, longevity and productivity of your cows.

Cyclone 360 with MISTING: the ultimate solution against heat stress

To further enhance the thermal comfort management of your herd, the Cyclone 360 can be equipped with a high-pressure misting system.

This combination combines the ventilation power of the Cyclone with the refreshing efficiency of a fine mist. This mist reduces the ambient temperature by up to 5 °C and optimizes animal welfare even during heat waves.

An ideal solution to limit production losses related to heat stress and sustainably improve the health and well-being of your cows.

Control Modes for the Cyclone 360 Fan

To provide consistent thermal comfort for your cows while optimizing electricity consumption, the Cyclone 360 has several control solutions.

Building temperature control

Manual potentiometer

Manual adjustment system

1 potentiometer/Cyclone

The potentiometer allows immediate adjustment of the fan speed, ideal for quickly adapting ventilation in the milking parlor or waiting areas.

Autonomous Probe

Automatic adjustment system

1 probe/Cyclone

The probe automatically adjusts ventilation according to the temperature: shutdown in cool weather and progressive modulation in case of increase. The settings are defined in advance, guaranteeing a stable climate without the need for adjustments.

CV 22 control box

Automatic regulation with adjustable parameters

1 box / 8 Cyclones

The CV 22 control box centralizes the management of several fans. Thanks to its optimized and adjustable pre-settings, it easily adapts to the size and configuration of each building, while allowing, if necessary, a switch to manual mode.

Heat stress control

Previous ventilation control solutions rely solely on the building's interior temperature. With Heat Stress Dynamic Control (HSDC), Bioret Agri takes it a step further: this intelligent system integrates both temperature and humidity to calculate the true THI.

Result: precise and responsive climate management that effectively protects your cows from heat stress and improves their comfort and performance.

HSDC: Heat Stress Dynamic Control

Smart control based on temperature, humidity, and customizable thresholds

1 HSDC / misting control unit (=16 cyclones)

Heat Stress Dynamic Control (HSDC) is an intelligent control system specifically designed to reduce heat stress in dairy buildings.

It relies on a network of temperature and humidity sensors that continuously monitor ambient conditions to calculate the THI. Using an adaptive algorithm, HSDC automatically adjusts ventilation and cooling to maintain a stable, comfortable indoor climate.

The process is progressive: as temperature rises, the fans start and gradually increase their speed as the THI increases. If this is not sufficient to maintain a cool environment, the system activates misting, combined with the fans to enhance the cooling effect. Finally, once the predefined THI threshold for your building is reached, the Aquaclim mattresses activate conduction cooling directly in contact with the animals.

This intelligent regulation maintains an optimal indoor climate at all times, without wasting energy or creating excess humidity. The result is a reliable, automated, and energy-efficient system that safeguards herd welfare and supports dairy production performance.

These different systems ensure flexible use, adapted to both weather conditions and the specific needs of each area of the barn, while ensuring responsible energy management.

Would you like more information on the Cyclone 360? Contact us!

They have tested and approved our products

Farmer Stories

Aquastar: “Cows no longer lie down in the alleys, even in hot weather”

Artemis pen: “From a health standpoint, it’s better for the animals”

To ensure it takes place under the best possible conditions, cows need comfort and impeccable hygiene

With the Artemis pen, you provide the optimal environment for safe and efficient calving...

Sani-Feed: “Feed is delivered to our cows under optimal hygiene conditions”

Cleaning becomes more difficult and hygiene can no longer be guaranteed

The feed bunk itself may then become a source of microbial contamination of the ration

By covering…