Accueil > Sols antidérapants pour vaches > Delta X

DELTA X®

Delta X : séparer les effluents à la source pour un élevage plus sain

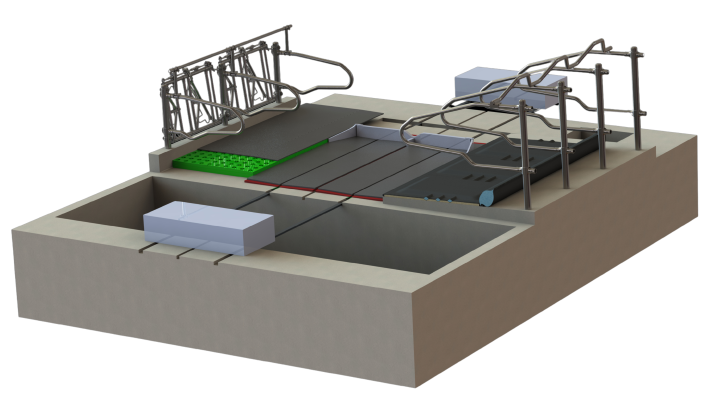

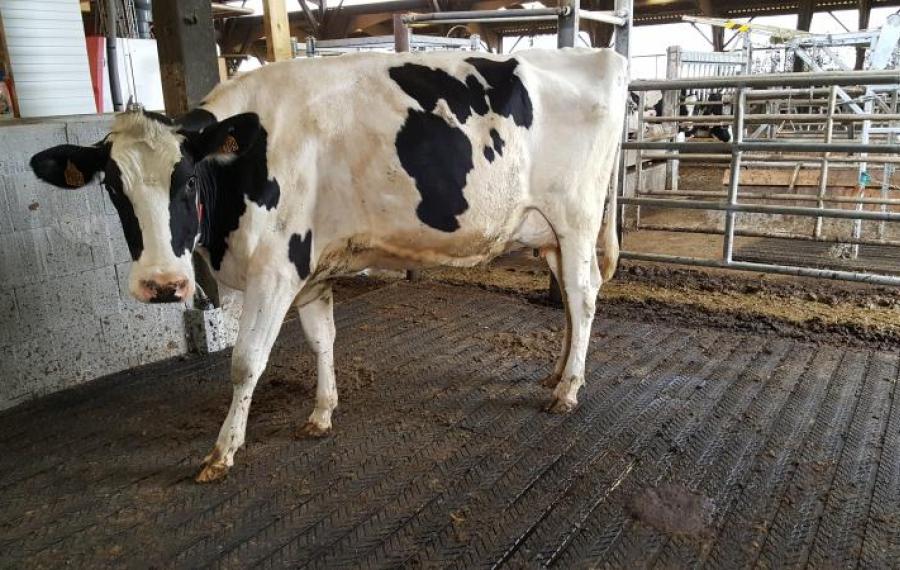

Le Delta X est un système innovant de séparation des effluents, conçu pour éviter la formation de lisier en séparant fèces et urines directement à la source. En limitant ce mélange, il réduit fortement les émissions d’ammoniac, mais aussi celles de CO₂, de méthane et de protoxyde d’azote. Résultat : une qualité de l’air améliorée dans l’étable et un environnement plus sain pour les animaux comme pour les éleveurs.

Compact et discret, le Delta X s’intègre directement dans le sol des couloirs de circulation. Deux rigoles latérales, encastrées dans une pente de 3 %, dirigent naturellement les déjections solides vers un système de courroies motorisées. En mouvement continu, celles-ci évacuent en permanence les liquides vers une fosse de stockage extérieure.

Les bénéfices immédiats pour l’élevage :

- Un sol plus propre, limitant la prolifération bactérienne et les pathologies associées

- Une réduction significative des odeurs d’ammoniac

- Une hygiène renforcée dans les bâtiments d’élevage

- Une ambiance plus saine, bénéfique au bien-être animal et aux conditions de travail du personnel

Delta X : préserver la valeur agronomique des effluents

Un autre atout majeur du Delta X est sa capacité à préserver la valeur agronomique des effluents.

- Les urines, collectées directement à la source, conservent tout leur potentiel azoté, permettant leur valorisation en bio-stimulant naturel, idéal pour une agriculture circulaire et respectueuse de l’environnement.

- Les matières solides, séparées et assainies, peuvent être transformées en bio-compost de haute qualité, adapté à de nombreux usages agronomiques.

Le Delta X s’installe aussi bien dans un bâtiment neuf que dans le cadre d’une rénovation, sans perturber la circulation des animaux. Son fonctionnement repose sur une consommation énergétique réduite, limitant les coûts d’exploitation tout en s’inscrivant dans une démarche durable.

Delta X, c’est une technologie propre et efficace, conçue pour rendre les exploitations plus durables, hygiéniques et économiquement performantes.

Vous souhaitez plus d'informations sur le Delta X ? Contactez nous !

Ils ont testé et approuvé nos produits

Retours d’expérience

Aquastar : « Il n’y a plus de vaches couchées dans le couloir, même quand il fait chaud »

Box Artémis : « Sanitairement c’est mieux pour les animaux. »